Nanomaterials synthesis

- Continuous Microfluidic Synthesis

- Continuous Laser Pyrolysis Reactors

- Microwave-Assisted Synthesis Of Nanomaterials

CONTINUOUS MICROFLUIDIC SYNTHESIS

Most laboratory-scale syntheses of nanomaterials consist of complex, multistep processes that yield a few tens of milligrams of product per batch. Conventional batch reactors suffer from serious limitations due to the inefficient heat and mass transfer that makes it very difficult to achieve an accurate control on the synthesis conditions. This has a direct effect on key aspects such as reproducibility, selectivity and scalability. In fact, one of the bottlenecks in the development of Nanotechnology lies in the lack of precise synthesis methods capable of a scaled up production.

Our approach

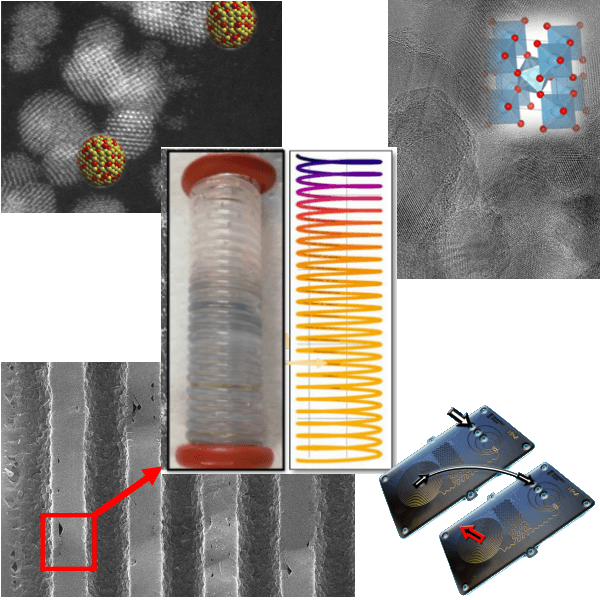

Continuous flow reactors based on microfluidic principles offer potential solutions to the aforementioned concerns. The exquisite control afforded by microfluidic reactors enables continuous production of nanocrystals with well‐defined sizes, shapes and composition. We have designed versatile synthesis microfluidic platforms to produce a broad library of nanostructures in a continuous fashion, often with a strong reduction of processing times with respect to the corresponding batch process. We have shown that even complex multistage processes can be translated into continuous microfluidic production. Also, we use segmented flow reactors not only to homogenise residence time distributions, but also to attain unprecedented flexibility in terms of tuning the reaction atmosphere. Finally, the high control of contact modes and times afforded by microfluidics enables emerging applications such as exosome capture.

Some recent related publications

- Continuous Microwave-Assisted Synthesis of Silver Nanoclusters Confined in Mesoporous SBA-15: Application in Alkyne Cyclizations. Manno R.; et al., Chem. Mater., 32 2874–2883 (2020). http://doi.org/10.1021/acs.chemmater.9b04935

- Customized hybrid and NIR-light triggered thermoresponsive drug delivery microparticles synthetized by photopolymerization in a one-step flow focusing continuous microreactor. Ortiz de Solorzano I.;et al., Colloids and Surfaces B: Biointerfaces, 190, 110904 (2020). http://doi.org/10.1016/j.colsurfb.2020.110904

- Isolation of exosomes from whole blood by a new microfluidic device. Proof of concept application in the diagnosis and monitoring of pancreatic cancer, M. Sancho-Albero, V. Sebastian, J. Sesé, R. Pazo-Cid, G. Mendoza, M. Arruebo, M.P. Martin Duque, J. Santamaria, J. Nanobiotechnol., 18:150, (2020). https://doi.org/10.1186/s12951-020-00701-7

- Gas-Directed Production of Noble Metal-Magnetic Heteronanostructures in Continuous Fashion: Application in Catalysis. Larrea A.; et al., ACS Appl. Mater. Interfaces, 11, 43520-43532 (2019). http://doi.org/10.1021/acsami.9b15982

- Continuous Microfluidic Synthesis of Pd Nanocubes and PdPt Core–Shell Nanoparticles and Their Catalysis of NO2. Reduction Pekkari A.; et al., ACS Appl. Mater. Interfaces, 11, 36196–36204 (2019). http://doi.org/10.1021/acsami.9b09701

Contact persons

Santamaría, Jesús: jesus.santamaria@unizar.es

Sebastián, Víctor: victorse@unizar.es

CONTINUOUS LASER PYROLYSIS REACTORS

Most processes for nanomaterials synthesis use liquid phase routes. However wet routes sometimes face important limitations, such as the solubility of the precursors and the post processing steps needed to remove the liquid from the solid nanoparticles. Gas phase processes would be advantageous in this respect, and also regarding the fast nanoparticle synthesis kinetics that are often possible in the gas phase. However, these processes face the problem of nanoparticle agglomeration that occurs quickly in the gas phase and also on the filters used to collect the product nanoparticles. Laser pyrolysis is an important, and still scarcely explored, nanoparticle synthesis technique that allows continuous nanoparticle production while solving part of the above problems.

Our approach

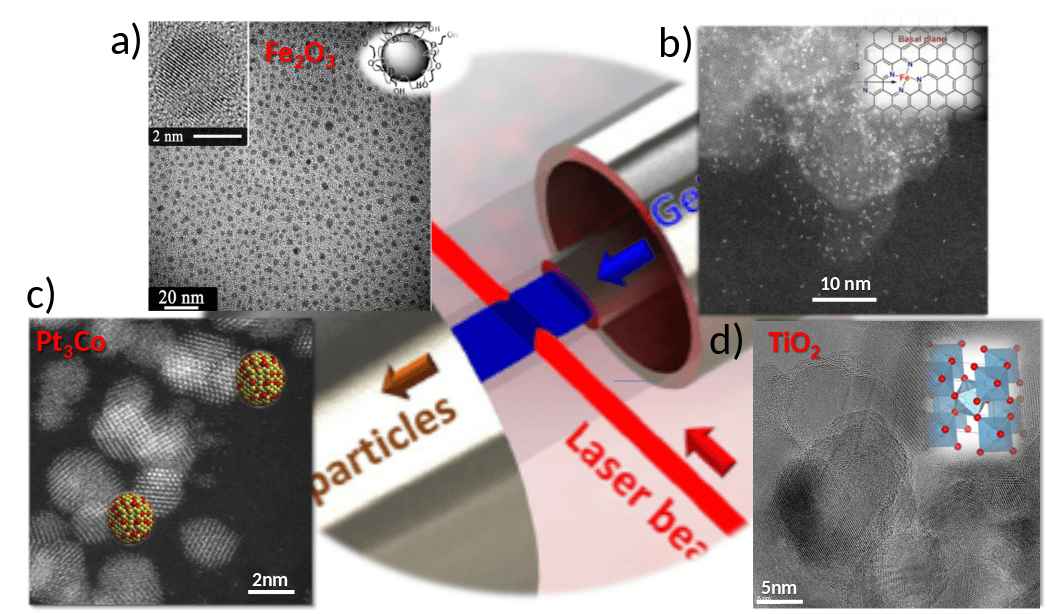

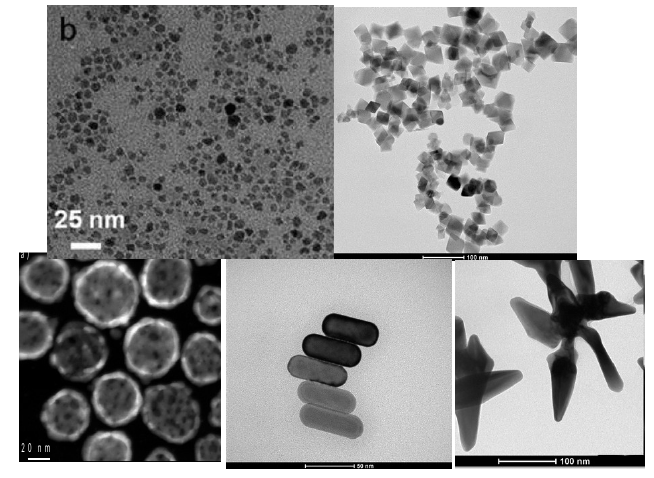

Our laser pyrolysis unit uses a laser beam to selectively heat a gas stream containing one or more chemical precursors that decompose, inducing nucleation of nanoparticles. The short, well-controlled residence time in the reaction zone is especially suitable for the production of very fine homogeneous nanoparticles. In addition, we have developed liquid collection systems that minimize agglomeration and we are able to use not only gas but also liquid and solid phase precursors, thanks to a mist chamber that allows the feeding of micron-size aerosols. The nanomaterials synthesized have been used in a range of applications, from energy and electro-catalysis to nanomedicine.

Figure: Examples of nanomaterials synthesized in our laser pyrolysis reactor. A) TEM image of monodispersed magnetic nanoparticles (3-5 nm) collected in a polyol liquid medium (inset: HRTEM image of an individual nanoparticle). B) Carbon supported Single-Atom Catalysts with Fe-N active centers. C) STEM-HAADF image of 2-4 nm Pt3Co/C alloy nanoparticles. D) TEM image of 15-20 nm TiO2 nanoparticles.

Highlighted and recent publications

- Nitrogen-doped carbon nanodots deposited on titania nanoparticles: unconventional near-infrared active photocatalysts for cancer therapy. A. Madrid, A. Martin-Pardillos, J. Bonet-Aleta, M. Sancho-Albero, G. Martinez, J. Calzada-Funes, P. Martin-Duque, J.Santamaria, J.L. Hueso, Catal. Today, 419, 114154, (2023). https://doi.org/10.1016/j.cattod.2023.114154

- Laser-driven direct synthesis of carbon nanodots and application as sensitizers for visible-light photocatalysis. Mas, N., Hueso, J.L., Martinez, G., Madrid, A., Mallada, R., Ortega-Liebana, M.C., Bueno-Alejo, C., Santamaria, J., Carbon, 156, pp. 453-462, (2020). https://doi.org/10.1016/j.carbon.2019.09.073

- Laser-Assisted Production of Carbon-Encapsulated Pt-Co Alloy Nanoparticles for Preferential Oxidation of Carbon Monoxide. G. Martinez; et al., Frontiers in Chemistry, 6, 487 (2018). https://doi.org/10.3389/fchem.2018.00487

- Facile production of stable silicon nanoparticles: laser chemistry coupled to in situ stabilization via room temperature hydrosilylation, A. Malumbres; et al., Nanoscale, 7, 8566-8573 (2015) https://doi.org/10.1039/C5NR01031D

- Continuous-mode laser ablation at the solid-liquid interface of pelletized low-cost materials for the production of luminescent Silicon Carbide nanocrystals, M.C. Ortega-Liébana, J.L. Hueso, R. Arenal, R. Lahoz, G.F. de la Fuente, J. Santamaria, J. Phys. Chem. C., 119, 2158-65, (2015). https://pubs.acs.org/doi/10.1021/jp509594g

Contact persons

Hueso, José Luis: jlhueso@unizar.es

Mallada, Reyes: rmallada@unizar.es

Martínez, Gema: gemamar@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

MICROWAVE-ASSISTED SYNTHESIS OF NANOMATERIALS

Microwave heating possesses distinctive features compared to conventional heating allowing ultrafast volumetric heating and especially selective heating for suitable materials. These characteristics can be leveraged to prepare nanomaterials that otherwise could not be easily produced by conventional heating methods. Also, higher energy efficiency can be expected as already shown in the food industry. However, microwave-driven synthesis of nanomaterials needs a precise control of local temperature and the design of microwave cavity together and of the reactor where synthesis takes place are key aspects.

Our approach

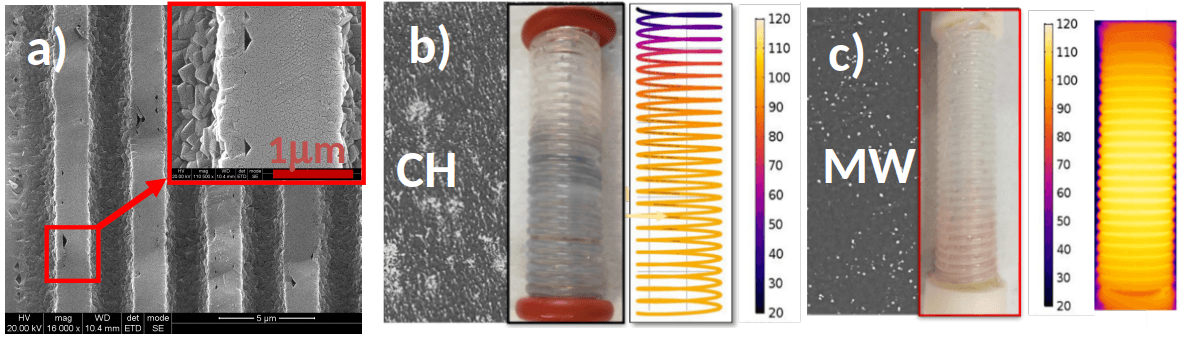

Fast heating is directly related to the reduction of synthesis time but also results in other advantages. Thus, we were able to synthesize a thin layer of silicalite on silicon micropillars in 3 minutes, but the short synthesis time also avoided the dissolution of silicon on the basic synthesis gel (Figure (a)). Also, the synthesis of materials at high temperatures, with short contact time and fast cooling is a good strategy for stabilizing metastable phases that otherwise could not be synthesized under conventional heating. The synthesis of nanoclusters is possible using this principle, avoiding further growth to bigger nanoparticles. Microwave synthesis has also allowed us to exfoliate 2D microwave-absorbing materials with high size and unprecedented yields.

Figure: a) Synthesis of silicalite layer on Si micropillar under microwaves (MW) in 3 minutes, b) Synthesis of Ag nanoparticles in continuous millifluidic reactor under conventional heating (CH) and c) microwave heating (MW).

Some recent related publications

- Microwave-driven exfoliation of bulk 2H-MoS2 after acetonitrile pre-wetting produces large-area ultrathin flakes with exceptionally high yield, R. Quirós-Ovies, M. Laborda Cuartero, N. Martín Sabanés, L. Martín-Pérez, S. Moreno da Silva, E. Burzurí, V. Sebastian, E. M. Pérez, J. Santamaría, ACS Nano, 17, 5984-93 (2023). https://doi.org/10.1021/acsnano.3c00280

- Rapid Microwave Heating and Fast Quenching for the Highly Efficient Production of Long-term Stable Supported Ag Nanoclusters”, R. Manno, P. Ranjan, V. Sebastian, R. Mallada, S. Irusta, E.V. Van der Eicken, J. Santamaria, Catal. Today, 420, 114081, (2023). https://doi.org/10.1016/j.cattod.2023.114081

- Continuous Microwave-Assisted Synthesis of Silver Nanoclusters Confined in Mesoporous SBA-15: Application in Alkyne Cyclizations. Manno, R., RanjaN, P., Sebastian, V., Mallada, R., Irusta, S., Upendra K. Sharma, U.K., Van der Eycken E.V., Santamaria, J., Chem. Mat. 32, 7, 2874–2883, (2020). https://doi.org/10.1021/acs.chemmater.9b04935

- Ultra-Small Silver Nanoparticles Immobilized in Mesoporous SBA-15. Microwave-Assisted Synthesis and Catalytic Activity in the 4-Nitrophenol Reduction. Manno, R., Sebastian, V., Irusta, S., Mallada, R., Santamaria, J. Catal. Today, In press (2020). https://doi.org/10.1016/j.cattod.2020.04.018

- Nucleation of Ag nanoparticles in helical microfluidic reactor. Comparison between microwave and conventional heating Manno, R., Sebastian, V., Mallada, R., Santamaria, J. Ind. Eng. Chem. Res., 58 (28), pp. 12711-12711, (2020). https://doi.org/10.1021/acs.iecr.9b01460

Contact persons

Mallada, Reyes: rmallada@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

Sebastián, Víctor: victorse@unizar.es

Nanomaterials for energy, environment and safety

- Molecular Recognition: Detection Of Hazardous Compounds

- Environmental Photocatalysis

- Nanomaterials for Solar Energy Harvesting

- Nanomaterials for Energy Storage

- Nanosafety: Safe Handling Of Nanomaterials

MOLECULAR RECOGNITION: DETECTION OF HAZARDOUS COMPOUNDS

While many types of chemical sensors display remarkable sensitivity (e.g. down to the femtogram level for cantilever mass sensors) they often lack selectivity, reacting similarly to a variety of substances. New sensors are needed that are not only fast, inexpensive and sensitive, but also highly selective, capable of discriminating among different molecules in a mixture. This is of major importance in the CBRNe field. Although currently extremely rare, CBRNe incidents pose a very significant threat to society. There is a need for technologically advanced tools and equipment that are affordable and innovative to rapidly identify and analyse threats.

Our approach

We concentrate our efforts in the detection of explosives and chemical warfare agents.

- Electronic nose approach

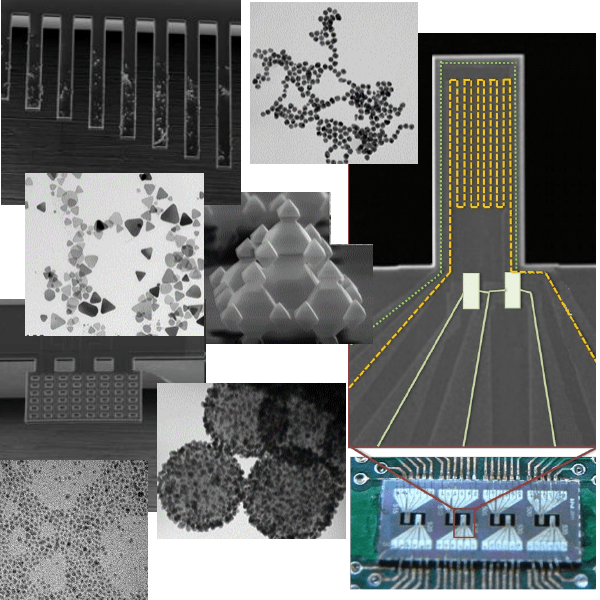

We explore the combination of nanoporous solids and highly sensitive cantilevers arrays configured as an electronic nose. We have employed the molecular recognition capabilities of nanoporous solids (zeolites, titanosilicates, MOFs and mesoporous silicas) often functionalized to enhance their selectivity. The nanoporous materials are deployed on mechanical transducers with the aim of serving either as a target for the desired species, or as a barrier for interfering components.

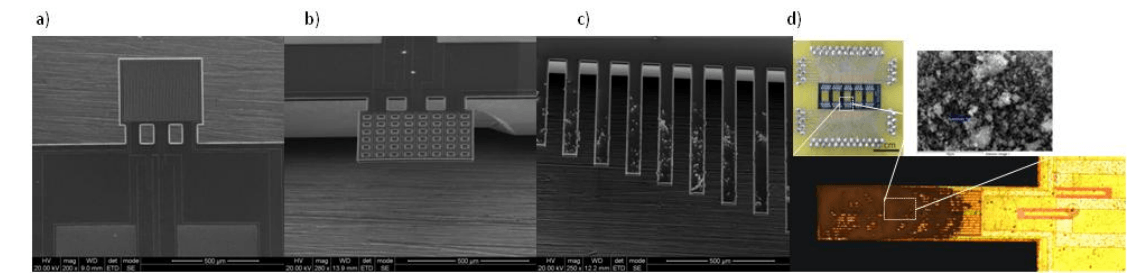

Figure: Different Si based cantilever designs for gas sensing applications: a,b) different magnification before discrete zeolite crystals deposition and c,d) after discrete zeolite crystals deposition.

A workable electronic nose requires miniaturization of its components, for economic as well as for practical (fast detection, regeneration times for efficient operation and system integration) reasons. We have developed a new generation of cantilevers based on nanoporous solids capable of achieving detection limits towards explosive vapours down to 400 ppbV. A precise temperature control on the cantilever allows us to track regeneration and also to enhance the combinatorial selectivity of the platform by measuring with temperature modulation.

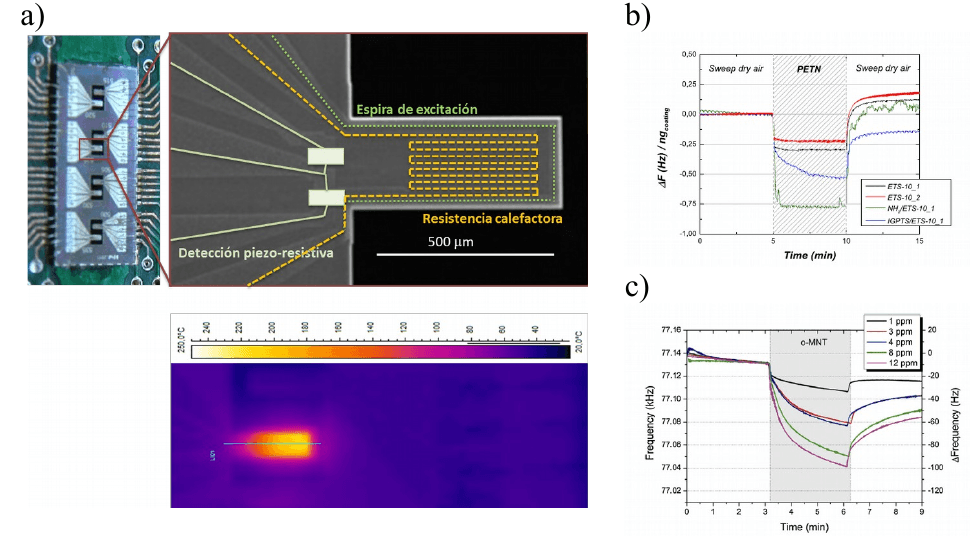

Figure: Electronic nose based on Si micro-cantilevers coated with nanoporous materials working in dynamic mode. a) Chip design (top) and temperature profile (bottom) during degassing step, b) evolution of the resonance frequency shift of the multisensing platform based modified with titanosilicates in presence of vapors emanating from solid PETN at 343K and c) evolution of the resonant frequency of Co-BEA modified cantilever upon the introduction of 2-nitrotoluene (o-MNT) vapors at room temperature.

- SERS based approach.

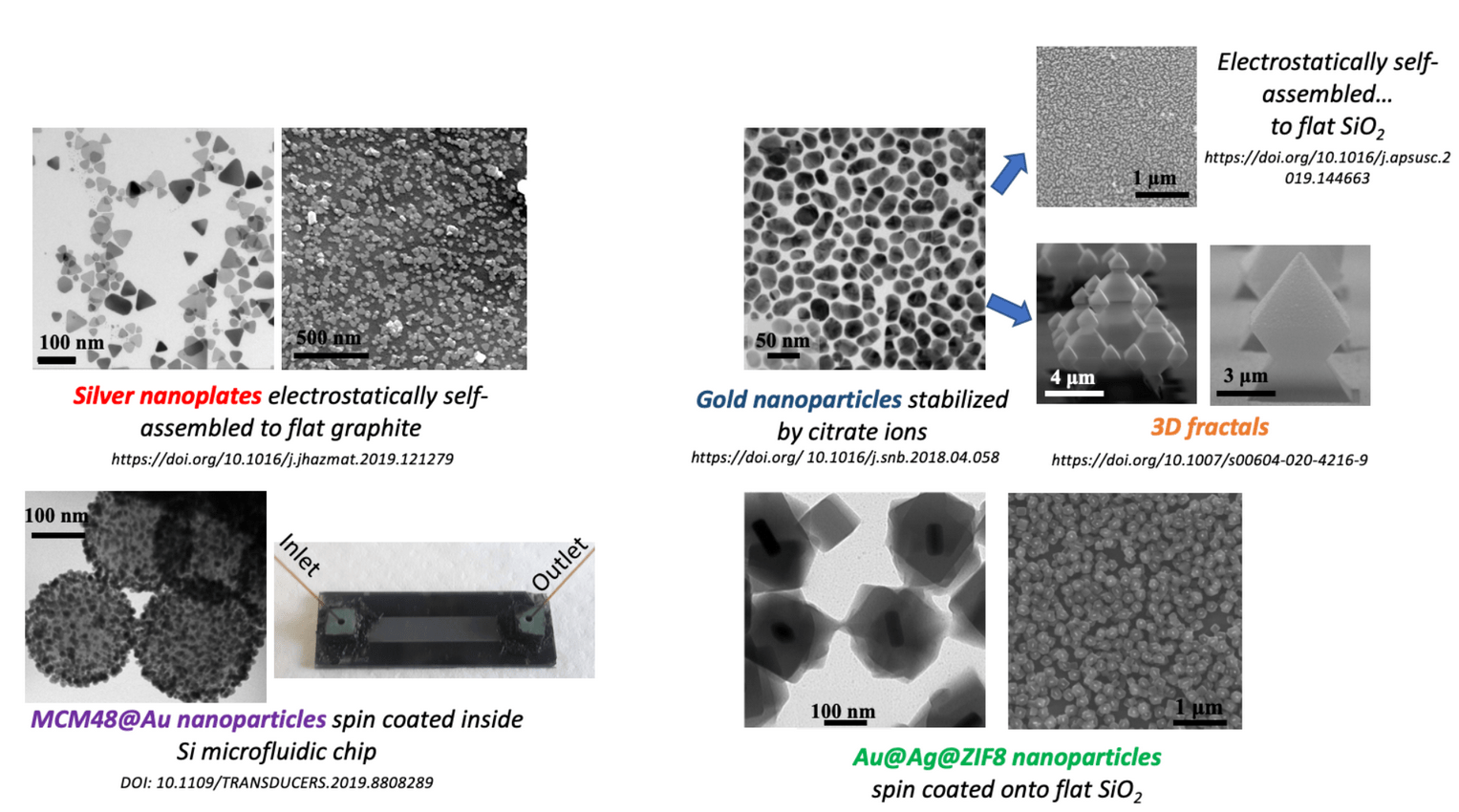

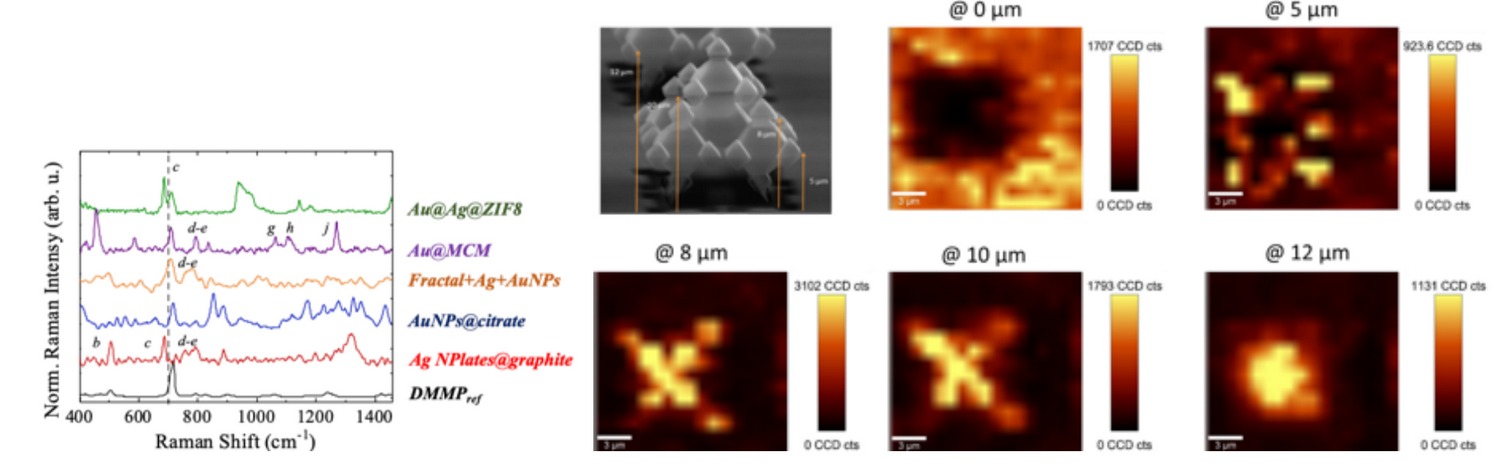

Surface-enhanced Raman spectroscopy (SERS) is one of the leading techniques for label free ultrasensitive vibrational fingerprinting of a variety of molecular compounds. Surface design is key in SERS as strongly enhanced Raman scattering only occurs in very close vicinity (typically less than 10 nm) of the metal when localized surface plasmon nodes are excited. This is even more important for chemical warfare agents (CWAs) that are regarded as poor Raman scatterers. Our approach relies on the functionalization of the SERS surface for trapping of target analyte. Recently, we have demonstrated how the capping agent of metallic NPs can perform as an effective molecular trap by reversible adsorption of neurotoxic agent molecules allowing continuous SERS sensing with limit of detection values down to 130 ppbV. One of the main limitations of the surface-enhanced Raman scattering (SERS) technique as an analytical tool relies on the homogeneity, reproducibility and re-usability of the substrates. In this sense, we are also collaborating with the University of Twente in the development of SERS active platforms from top-down approaches (i.e. 3D-fractal microstructures).

Figure: Different plasmonic nanostructures and SERS substrates developed for neurotoxic agent detection in gas phase.

Figure: SERS Response of different SERS substrates. right) Comparison of SERS spectra when exposed to 2.5 ppmV of dimethyl methylphosphonate DMMP (mimicking compound for neurotoxic agents) with the characteristics Raman features of liquid DMMP underlined in yellow; left) Raman signal mapping of the R6G characteristic band at 1512 cm-1 across a 20 × 20 µm at different heights (z-position) from the bottom: 0 µm (bottom surface); 5 µm; 8 µm; 10 µm; 12 µm.

Some recent related publications

- SALDI-MS and SERS Multimodal Imaging: One Nanostructured Substrateto Rule Them Both. Iakab, S-A., Baquer, G., Lafuente, M., Pina, M.P., Ramírez, J.L., Ràfols, P., Correig-Blanchar, X., García-Altares, M. Anal. Chem. 94-6, 2785-2793 (2022).. https://doi.org/10.1021/acs.analchem.1c04118

- Plasmonic MOF thin films with raman standard for fast and ultrasensitive SERS detection of chemical warfare agents in ambient air. Lafuente, M., de Marchi, S., Urbiztondo, M.A., Pastoriza-Santos, I., Perez-Juste, J., Santamaria, J., Mallada, R., Pina, M.P. ACS Sensors 6-6, 2241-2251 (2021). https://doi.org/10.1021/acssensors.1c00178

- A multiparameter gas-monitoring system combining functionalized and non-functionalized microcantilevers Huber, C., Pina, M.P., Morales, J.J., Mehdaoui, A. Micromachines, 11 (3), art. no. 283, (2020). https://doi.org/10.3390/mi11030283

- Attomolar SERS detection of organophosphorous pesticides using silver mirror–like micro-pyramids as active substrate. Lafuente, M., Berenschot, E.J.W., Tiggelaar, R.M., Rodrigo, S.G., Mallada, R., Tas, N.R., Pina, M.P. Microchimica Acta, 187 (4), art. no. 247, (2020). https://doi.org/10.1007/s00604-020-4216-9

- Cu-BTC Functional Microdevices as Smart Tools for Capture and Preconcentration of Nerve Agents. Almazan, F., Urbiztondo, M.A., Serra-Crespo, P., Seoane, B., Gascon, J., Santamaria, J., Pina, M.P. ACS Appl. Mater. Interfaces 12, 38, 42622-42633 (2020). https://doi.org/10.1021/acsami.0c07364

Contact persons

Mallada, Reyes: rmallada@unizar.es

Pina, María Pilar: mapina@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

Urbiztondo, Miguel: urbiz@unizar.es

ENVIRONMENTAL PHOTOCATALYSIS

The negative impact of greenhouse gas emissions and urban airborne pollutants together with the increasing scarcity of water are some of the XXI century major environmental challenges. Photocatalysts provide a greener technological alternative to face those challenges, taking advantage of an abundant and inexpensive source such as the sun or, alternatively making use of highly efficient artificial lights. In spite of its potential, its use is still limited by the low efficiency of existing photocatalytic materials and reactors.

Our approach

We actively pursue the development of novel photocatalytic systems and photoreactor designs able to maximize the photo-response beyond the UV range. Typically, our photocatalysts are hybrid nanostructured materials that combine light-harvesting capability and highly desirable adsorptive and catalytic features. Also, we aim to reactor design able to maximize efficient light use and to minimize catalyst deactivation, often a problem in photocatalytic reactors.

Our efforts focus on two main research lines:

- Use of carbon dioxide as a chemical feedstock to produce added-value chemicals,mainly by using visible/NIR light-assisted CO2 hydrogenation to yield short range alcohols and/or hydrocarbons. A special focus is set on the development of plasmonic photocatalysts and transition metals with strong absorption in the visible- near infrared range. We are also exploring the synergistic combination of photocatalysis and photothermal response to increase reaction rates.

- Photodegradation of organic pollutants. Here the combination of conventional semiconductor titania with lower band gap semiconductors, or heterogeneous Fenton catalysts with nitrogen-doped carbon dots that act as photosensitizers seems especially promising. Finally, we are also interested in studying fluidized-bed photoreactor configurations to maximize the exposure of the photocatalysts to irradiation and in the use of plasmonic photocatalysts with visible-NIR expanded response.

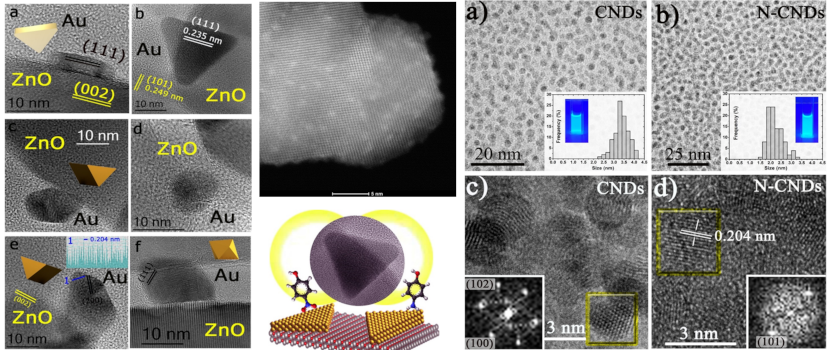

Figure: Selection of NFP photocatalysts: (left) Anisotropic gold nanoprisms and nanotriangles supported onto ZnO semiconductor nanoparticles; (centre): Photodeposited Ni nanoparticles onto TiO2 nanostructures; (right): Undoped and N-doped carbon nanodots retrieved from mesoporous silica templates

Highlighted and recent publications

- LED-driven controlled deposition of Ni onto TiO2 for the visible-light expanded conversion of carbon dioxide into C1-C2 alkanes, A. Sanz-Marco, J.L. Hueso, V. Sebastian, D. Nielsen, S. Mossin, J.P. Holgado, C.J. Bueno Alejo, F. Balas, J. Santamaria, Nanoscale Advances, 3, 3788-98, (2021). https://doi.org/10.1039/D1NA00021G

- Anisotropic Au-ZnO photocatalyst for the visible-light expanded oxidation of n-hexane. Bueno-Alejo, C. et al.; Catalysis Today, Volume 362, 97-103 (2021) https://doi.org/10.1016/j.cattod.2020.03.063

- LED-driven continuous flow carbon dioxide hydrogenation on a nickel-based catalyst. Bueno-Alejo, C. et al.; Catalysis Today, Volume 355, 678-684 (2020) https://doi.org/10.1016/j.cattod.2019.06.022

- Photocatalytic and antimicrobial multifunctional nanocomposite membranes for emerging pollutants water treatment applications. Salazar H.; et al.;Chemosphere Volume 250, 126299 (2020). https://doi.org/10.1016/j.chemosphere.2020.126299

- High-radiance LED-driven fluidized bed photoreactor for the complete oxidation of n-hexane in air. Bueno-Alejo, C. et al.; Chem. Eng. J., 358, 1363-1370, (2019). https://doi.org/10.1016/j.cej.2018.09.223

- Extraordinary sensitizing effect of co-doped carbon nanodots derived from mate herb: Application to enhanced photocatalytic degradation of chlorinated wastewater compounds under visible light., Ortega-Liebana, M.C. et al.; Appl. Catal. B. Environ. 218, 68-79, (2017). https://doi.org/10.1016/j.apcatb.2017.06.021

Contact persons

Balas, Francisco: fbalas@unizar.es

Bernechea, María: mbernechea@unizar.es

Hueso, José Luis: jlhueso@unizar.es

Lobera, M. Pilar: plobera@unizar.es

Mallada, Reyes: rmallada@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

Sebastián, Víctor: victorse@unizar.es

NANOMATERIALS FOR SOLAR ENERGY HARVESTING

Energy consumption is rising globally due to increased industrialization and population growth. Solar energy represents a massive, underutilised, and free source of energy. The Earth receives solar energy at a rate of 165,000 terawatts of power continuously, which is more than sufficient to meet current (approximately 15 TW) and projected future (60 TW) annual worldwide energy consumption. Photovoltaic solar cells, which employ semiconductor materials to convert sunlight into electrical power, are considered a fundamental technology for supplying sustainable, low-carbon energy to the world. Our research approach aims to develop new nanomaterials, nanoarchitectures and thin-films capable of harvesting and storage solar power more efficiently and sustainably.

1. Building-Integrated Photovoltaic Systems (BIPVS)

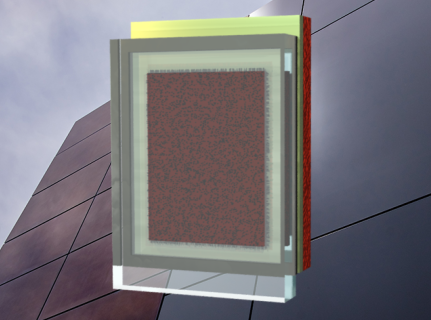

Our research in BIPVS focuses on developing low-cost photovoltaic cells for architectural integration using easily scalable assembly methods for the ceramic manufacturing sector (Figure 1). While these cells may not initially compete in terms of high efficiency for solar energy conversion per unit area, their use as architectural elements covering large surfaces and building facades will compete in net daily energy production. They also have the advantage of lacking the visual impact and high weight that prevents conventional photovoltaic solar panels from being safely installed and certified on ventilated facades. Our work in this area could position the market with a groundbreaking and innovative concept. The synergy between the University of Zaragoza’s expertise in hybrid halide perovskite photovoltaics[1,2] and the local ceramic industry’s leadership in building envelopes is crucial for this research, combining academic innovation with practical manufacturing knowledge to develop commercially viable BIPVS solutions.

Figure 1: The BIPV concept.

2. Photobatteries

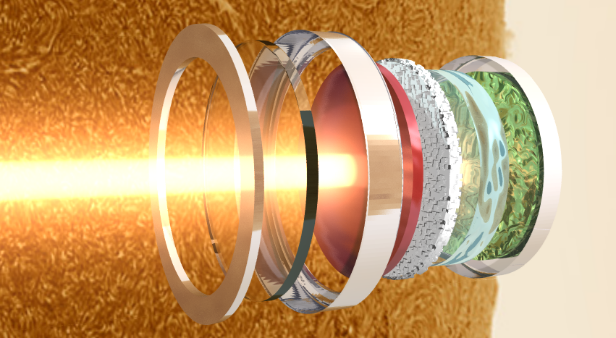

Our research in photobatteries aims to integrate solar energy harvesting and storage capabilities into a single device. Our recent work has demonstrated the concept of a photoelectrode capable of intercalating/deintercalating lithium ions when illuminated, using a Cu2O/TiO2 system[3]. This proof of concept has shown promising results in terms of photochargeable battery efficiency and capacity (Figure 2).

Figure 2: The Cu2O/TiO2 photochargeable battery system[3].

Building on this success, we are now exploring the use of halide perovskite materials as light harvesters in photobatteries. The exceptional optical properties of perovskites, combined with their solution processability, make them ideal candidates for integration into these hybrid devices. Our ultimate goal is to develop a highly efficient, stable photobattery that can be seamlessly integrated with our Building-Integrated Photovoltaic Systems (BIPVS) technology. This integration could lead to building materials that not only generate electricity from sunlight but also store it for later use, significantly enhancing the energy autonomy of buildings and contributing to the development of sustainable, energy-efficient architecture.

3. Green Solvent Perovskite Solar Cell Technology

Our research also extends to the development of perovskite solar cells using green and sustainable solvents (Figure 3). This approach aims to minimize the environmental impact of perovskite synthesis and facilitate early industrialization. We are exploring the use of eco-friendly solvents for dissolving perovskite precursors, focusing on both lead-free tin-based perovskites and lead-based perovskites synthesized in the ambient atmosphere. This research contributes to the transition towards greener photovoltaic manufacturing technology while addressing practical problems related to the current energy crisis.

Figure 3: Green Solvent Perovskite Solar Cell Technology.

4. Nanomaterials for solar cells

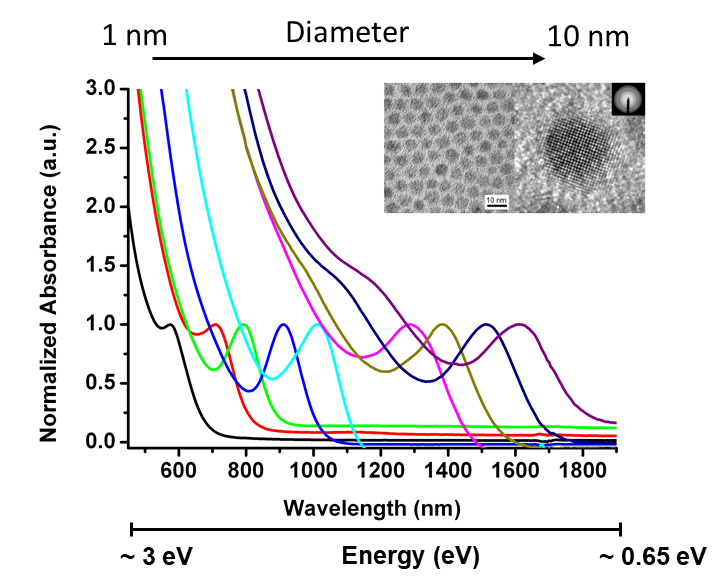

The use of colloidal nano-sized semiconductors reduces the fabrication cost of devices, and facilitates transference to industry. Since synthesis and deposition occur at different stages, it is easier to stabilise photoactive phases, control absorption range, and combine different materials (Figure 4). We focus on the development of materials based on abundant and non-toxic elements to reduce health and environmental concerns while ensuring availability for large scale production.

Figure 4: Band gap variation with nanoparticle diameter of colloidal PbS quantum dots.

5. Facilities

5.1 Open Solar Stability (OSS) Ecosystem

To address the critical issue of operational stability in perovskite solar cells (PSCs), we have developed the Open Solar Stability (OSS) ecosystem. This comprehensive approach aims to standardize and improve the evaluation of operational stability in PSCs and other emerging photovoltaic technologies. The OSS ecosystem offers several advantages, including open-source (https://github.com/ej-jp/perovskino) and low-cost design, realistic testing conditions, statistical significance through high-throughput testing, and a comprehensive assessment combining outdoor and laboratory experiments. This approach has the potential to accelerate stability improvements in PSCs, facilitate meaningful comparisons between different cell architectures and materials, and bridge the gap to commercialization by providing data that more accurately reflects real-world performance. Our OSS ecosystem consists of three key components:

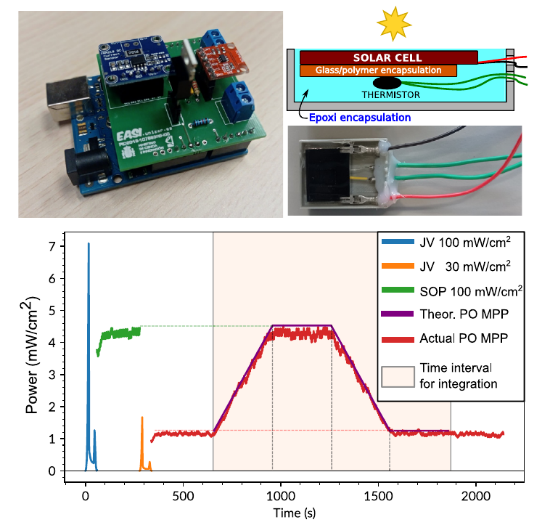

5.1.1 Perovskino: An advanced maximum power point (MPP) tracker that ensures solar cells operate at their optimal power output during testing, enabling realistic operational conditions assessment.[4]The Perovskino tracker employs a galvanostatic strategy for MPP search, making it particularly effective for perovskite solar cells regardless of their hysteresis. This device is used in both our outdoor testing platform and our laboratory resilience testing bench (Figure 5).

Figure 5: The Perovskino MPP tracker driving a high hysteresis perovskite solar cell[4].

5.1.2 ParaSol: An outdoor testing platform that exposes solar cells to real environmental conditions, capable of testing multiple devices at MPP (using the Perovskino tracker) simultaneously for statistically significant stability data. The Parasol platform is an outdoor testing facility capable of measuring up to 200 devices simultaneously with low-latency data collection. It provides real-time, online visualization of performance data for both silicon and perovskite solar cells (Figure 6). The platform is located on the terrace of the I+D+i Building at the Rio Ebro Campus of the University of Zaragoza.

Figure 6: Telegram channel providing real-time data from the ParaSol Platform.

5.1.3 ReSol: A laboratory-based testing bench focused on short-term thermal operational stability under simulated sunlight, potentiostat or galvanostat driving methods introducing a novel stability metric called the Irreversible Destruction Temperature (IDT).

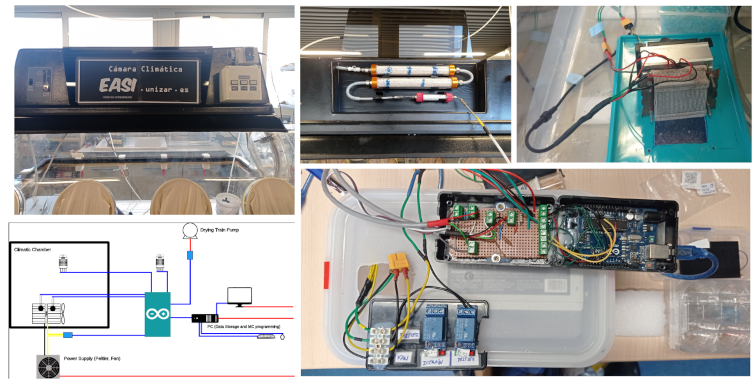

5.2 Other Facilities related to the preparation of emergent photovoltaics/photobatteries

Our lab features a custom climatic chamber with humidity control for spin coating perovskite thin films and nanoparticles under controlled temperature and humidity, enabling precise and reproducible film deposition (Figure 7). We also have a separate climate-controlled storage cabinet for long-term sample preservation, a lab vacuum glove box with anhydrous/anaerobic environment, and a vacuum thermal evaporator for metal back contacts. Additionally, LED and Xenon lamp solar simulators and a Bentham EQE (IPQE) equipment (300-1800 nm) enable us complete in-house fabrication and basic characterization of our solar cells.

Figure 7: Climatic chamber for PSC assembly. https://nfp.unizar.es/other-links/selected-ambient-works/

References

-

Perovskite solar cells take a step forward. E. J. Juarez-Perez, M. Haro, Science, 2020, 368, 1309-1309. https://doi.org/10.1126/science.abc5401

-

Formamidinium halide salts as precursors of carbon nitrides. I. Ciria-Ramos; N. Navascués; F. Diaw; C. Furgeaud; R. Arenal; A. Ansón-Casaos; M. Haro and E. J. Juarez-Perez. Carbon, 2022, 196, 1035-1046. https://doi.org/10.1016/j.carbon.2022.05.051

-

Solar Energy Storage Using a Cu2O-TiO2 Photocathode in a Lithium Battery. I. Ciria-Ramos; E. J. Juarez-Perez & M. Haro. Small, 2023, 2301244 https://doi.org/10.1002/smll.202301244

-

E. J. Juarez-Perez; C. Momblona; R. Casas & M. Haro. Enhanced power-point tracking for high-hysteresis perovskite solar cells with a galvanostatic approach Cell Reports Physical Science, 2024, 5, 101885 https://doi.org/10.1016/j.xcrp.2024.101885

Contact Persons

Bernechea, María: mbernechea@unizar.es

Juarez-Perez, Emilio J.: ejjuarezperez@unizar.es

Momblona, Cristina: cristinamomblona@unizar.es

Sanz Marco, Arturo: arturosmarco@unizar.es

NANOMATERIALS FOR ENERGY STORAGE

Energy Storage Systems (ESS) will play a fundamental role in reducing fossil fuel consumption and greenhouse gas emissions by providing solutions to store energy produced from renewable sources and to implement electrical vehicles.

Lithium-ion batteries (LIBs) are the dominant technology, but they use scarce, toxic and often unethically resourced materials for their fabrication, driving the need to develop novel and improved technologies to complement LIBs.

Our research approach focuses on developing new functional materials with tailored properties to improve electrochemical performance of ESS, aiming at using abundant and non-toxic materials. These improved materials and systems are expected to contribute to reducing our dependence on oil, gas, or coal, and drive the deployment of renewable energies and clean transport.

1. Na-ion batteries

Sodium ion batteries (NIBs) have emerged as the safer and more sustainable technology able to complement lithium-ion batteries in the global energy storage scenario. This is due to the low-cost and abundance of sodium and cathode/anode materials necessary in the manufacturing process, and enhanced safety in comparison with LIB.

After years of research, now it is known that the knowledge on electrode and electrolytes gathered from LIB cannot be easily extrapolated to NIB due to differences in physicochemical properties (e.g. coordination environment within the electrolyte and interfacial chemistry at the electrode surface) and size between sodium and lithium. In this context, our research focuses on developing new high voltage low cost cathodes, safer and more stable electrolytes, and improved hard carbon anodes for NIBs. We pay special attention to the structural and surface properties that allow us to improve the material’s performance.

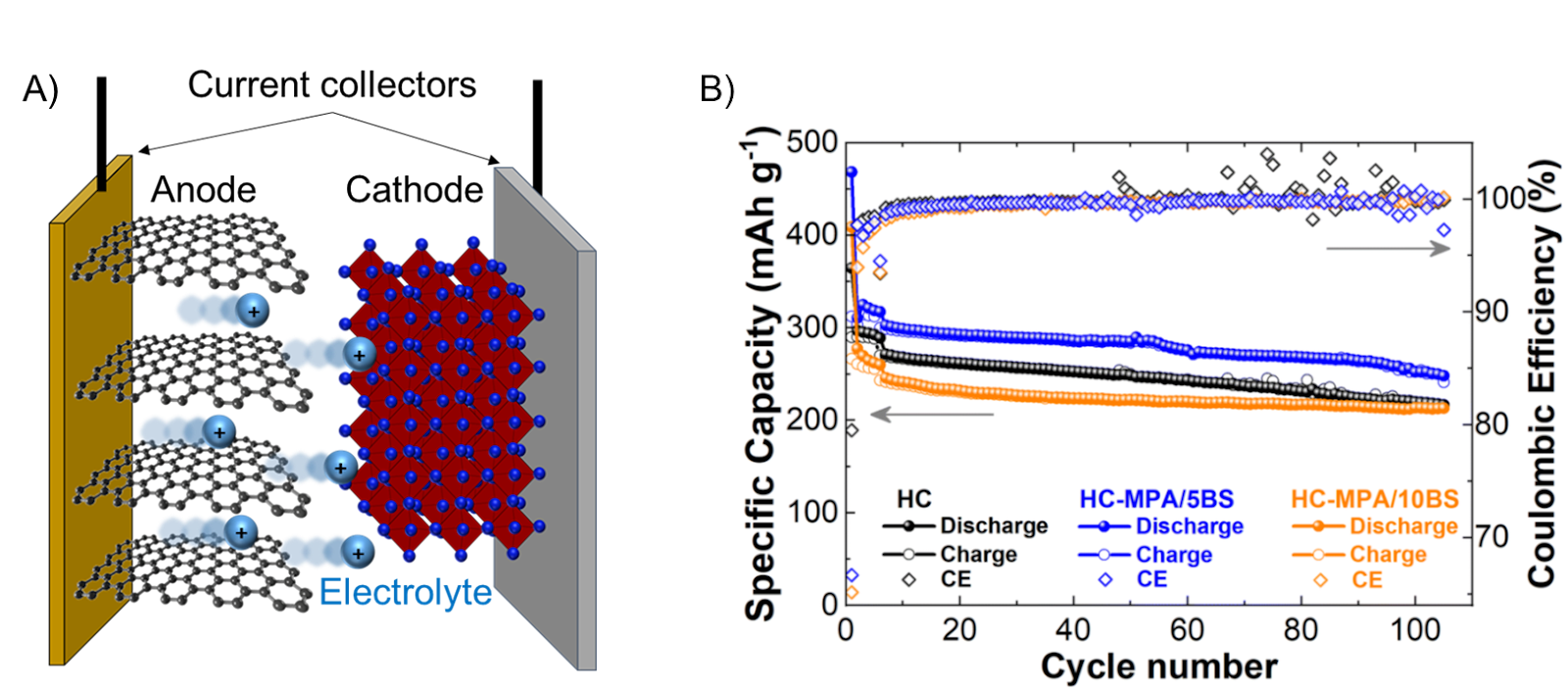

Figure 1. Na-ion batteries. (a) Schematic representation of Na-ion batteries. (b) Electrochemical curves of the prolonged cycling of hybrid electrodes (HC-MPA/BS). Charge/discharge capacities are presented on the left Y-axis and Coulombic Efficiency is presented on the right Y-axis.

2. Aqueous pseudo-capacitors

Supercapacitors are systems able to store energy by adsorbing electrolyte ions on the surface of the electrode material, for that reason, highly porous carbons are the ideal materials for these devices, however, their energy density is limited. This is even more critical when using water as solvent instead of organic solvents, because the reduced potential windows further limits the specific energy.

To overcome these limitations, we work on the development of redox active nanomaterials, used to fabricate nanomaterials/carbon composites, that have shown an improvement of the capacitance and the specific energy of aqueous supercapacitors.

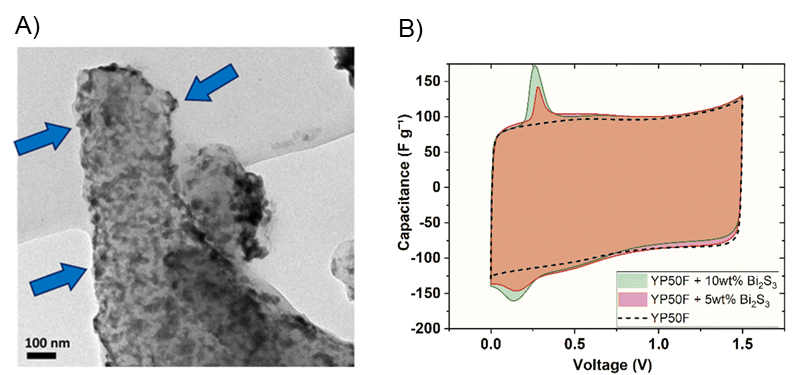

Figure 2. Supercapacitors. TEM image of hybrid carbonaceous nanocomposite showing a homogeneous distribution of NCs on the surface of the carbon. (A) 100 nm scale. Arrows indicate the location of NCs. (B) Electrode cyclic voltammograms of the symmetric cells with hybrid electrodes.

3. Li-ion Batteries

Although concerns about lithium scarcity initially drove interest in sodium-ion technology, new lithium deposits discovered in various parts of the world, including significant finds in Germany and the United States, have alleviated these supply (and ethical) concerns. Moreover, lithium-ion batteries offer several advantages over sodium-ion batteries, including higher energy density, lower self-discharge rates, and better performance at low temperatures. Lithium-ion batteries typically employ graphite in the anode and cobalt oxides in the cathode. However, these materials show limitations because of low intrinsic capacity or specific capacitance. Moreover, the production of battery-grade graphite or activated porous carbon derivatives involves resource and energy-intensive processes.

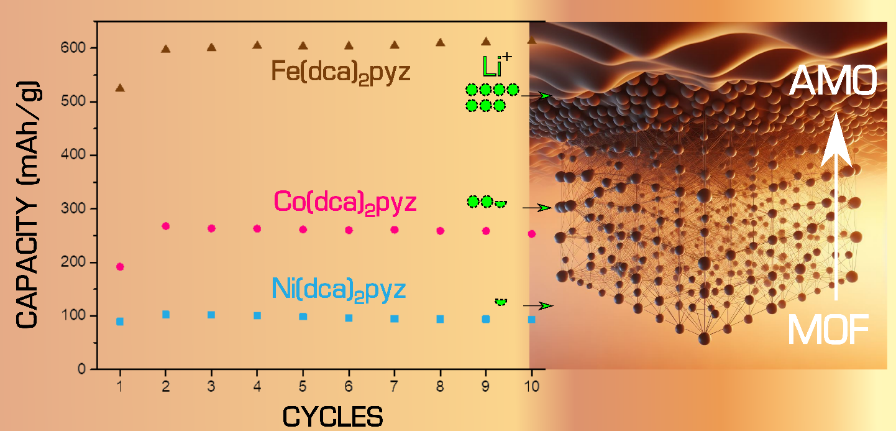

We have recently focused on exploring Metal-Organic Frameworks (MOFs) as environmentally friendly and electrochemically competitive electrodes for LIBs. Specifically, we have investigated a family of MOFs based on the ligands pyrazine (pyz) and dicyanamide (dca) with the unit formula M(dca)2pyz, where M represents transition metals such as Fe, Co, and Ni. A key finding of our research is the potential of AMorphous Organometallic (AMO) compounds as battery electrodes. These compounds can be obtained during battery operation by in situ amorphization of certain MOFs, without the need for heating the precursors at high temperatures or using aggressive chemical reagents for activation processes (Figure 3). This makes AMO compounds cost-effective and eco-friendly materials for electrodes. This study opens up a promising path for exploring MOFs as electrodes for lithium-ion batteries, potentially leading to more sustainable and efficient energy storage solution [5].

Figure 3. Cycling performance of Li-ion batteries employing the AMO concept.

Some recent related publications

1. High frequency response of adenine-derived carbon in aqueous electrochemical capacitor. Piwek J, Slesinski A, Fic K, Aina S, Vizintin A, Tratnik B, Lobera M.P, Bernechea M, Dominko R, Frackowiak E. Electrochimica Acta, 2022, 424, 140649. DOI: https://doi.org/10.1016/j.electacta.2022.140649.

2. Double redox aqueous capacitor with high energy output. Slesinski A, Sroka S, Aina S, Piwek J, Fic K, Lobera M.P, Bernechea M, Frackowiak E. J. Mater. Chem. A, 2023, 11, 6258-6273. DOI: https://doi.org/10.1039/D2TA09541F.

3. Exploring hybrid hard carbon/Bi2S3-based negative electrodes for Na-ion batteries. Tratnik B, Aina S, Tchernychova E, Gabrijelčič M, Mali G, Lobera M.P, Bernechea M, Morcrette M, Vizintin A, Dominko R. Green Chem., 2024. 1463-9262. DOI: 10.1039/D4GC00564C.

4. Simple surface treatment improves performance of carbon materials for sodium ion battery anodes. Aina S, Tratnik B, Vizintin A, Tchernychova E, Lobera M.P, Dominko R, Bernechea M. Journal of Power Sources, 2024, 610, 234730. DOI: 10.1016/j.jpowsour.2024.234730.

5. Electrochemical Performance of M(dca)2pyz (M= Fe, Co, and Ni) MOFs as Sustainable Anodes in Lithium-Ion Batteries. I. Ciria-Ramos; A. Garcia-Fernandez; A. Mayoral; A. Orera; E. J. Juarez-Perez & M. Haro. J. Mater. Chem.A, 2024, 12, 20215-20228 https://doi.org/10.1039/d4ta02137a

6. Sustainable conversion of vine shoots and pig manure into high-performance anode materials for sodium-ion batteries. Darío Alvira; Daniel Antorán; Hamideh Darjazi; Giuseppe Antonio Elia; Victor Sebastian; Joan J. Manyà. Journal of Power Sources, 614, 2024, 235043. https://doi-org.cuarzo.unizar.es:9443/10.1016/j.jpowsour.2024.235043

Contact persons

Bernechea Navarro, María: mbernechea@unizar.es

Juarez-Perez, Emilio J.: ejjuarezperez@unizar.es

Lobera, M. Pilar: plobera@unizar.es

Sebastian Cabeza, Víctor: victorse@unizar.es

NANOSAFETY: SAFE HANDLING OF NANOMATERIALS

Nanotechnology is expanding at a breathtaking pace with over 10000 nano-enabled products and a global market value exceeding 4 trillion (4×1012) dollars. However, understanding and assessing the potential environmental, human and safety issues (EHS) associated to nanomaterials exposure remains a challenge for researchers as well as for regulators.

Our approach

Rather than cell toxicity or in-vivo investigations, we focus our efforts on engineering approaches to tackle these EHS issues. No matter what risks are involved, we can always design handling and disposal procedures to avoid or minimize exposure. Also, we aim to develop tools to support environmentally relevant exposure models and more efficient and comprehensive testing procedures. Some of our unique capabilities in this respect are:

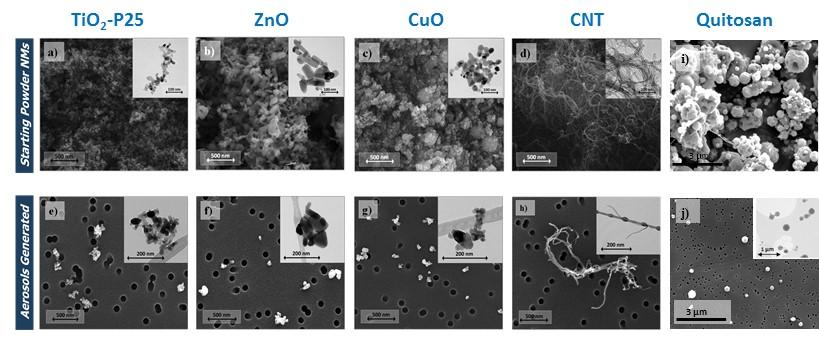

- Innovative Nanoparticle Aerosol Generators from dry powders [2].

Our patented technology allows a reliable aerosol generation from any preformed micro or nanoparticle powder. These aerosols with known and reproducible characteristics can then be used, e.g., on exposure tests with environmental models or for development and validation of methods for sampling and monitoring of airborne matter.

Figure 1. SEM and TEM images of the matter captured of an aerosol cloud.

- Self-cleaning nano-exposure chamber [5].

This facility allows the realistic simulation of industrial processes dealing with MNMs and nanoproducts, and validation of environmental and occupational exposure scenarios, in a controlled environment with continuous monitoring of nanoparticle aerosols.

Figure 2. Image of the airtight, self-cleaning nano-exposure chamber.

- Environmental monitoring of MNMs: [1,4].

Our approach is based in introducing trace amounts of labels (eg. rare earth oxides or flurorophores) that allow a reliable, ultrasensitive identification of MNMs in diverse matrices.

Figure 3. Deposition of nanoparticles in a simulated accidental aerosol generation during transfer of nanoparticles: The fluorescent emission of Ru(phen)3@SiO2 nanoparticles under LED illumination at 405 nm was apparent in several areas (walls, handling area, floor, gloves), inside the testing glove.

- Nanosafety assessment.

Our monitoring techniques can be used to measure and analyze the concentration levels and exposure of the MNMs at the workplace, as well as suitability of work procedures, as first step to diagnose the nano-safety situation.

Some recent related publications

- Fast and simple assessment of surface contamination in operations involving nanomaterials. Clemente, A. et al. J. Hazard. Mater. 363, 358-365, (2019). https://doi.org/10.1016/j.jhazmat.2018.10.011

- A Versatile Generator of Nanoparticle Aerosols. A novel tool in Environmental and Occupational Exposure Assessment. Clemente, A., et al., Science of the Total Environment, 625, 978-986, (2018). https://doi.org/10.1016/j.scitotenv.2017.12.125

- Modeling the size distribution in a fluidized bed of nanopowder. Fabre, A. et al. Environmental Science: Nano, 4 (3), 670-678 (2017). https://doi.org/10.1016/j.powtec.2017.02.056

- Fluorescently labelled SiO2 nanoparticles as tracers in natural waters: Dependence of detection limits on environmental conditions. Clemente A., et al. Environmental Science: Nano, 3(3), 631-637, (2016). https://doi.org/10.1039/C6EN00014B

- Development of a self-cleaning dispersion and exposure chamber: application to the monitoring of simulated accidents involving the generation of airborne nanoparticles. Clemente, A. et al. J. Hazard. Mater. 280, 226-234, (2014). https://doi.org/10.1016/j.jhazmat.2014.07.053

Contact persons

Balas, Francisco: fbalas@unizar.es

Lobera, M. Pilar: plobera@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

Novel catalysts and contactors

- LED-Illuminated Reactors

- Catalysts Capable Of Direct Heating In A Microwave Field

- Microconcentrators For Compounds At Trace Concentration Levels

LED-ILLUMINATED REACTORS

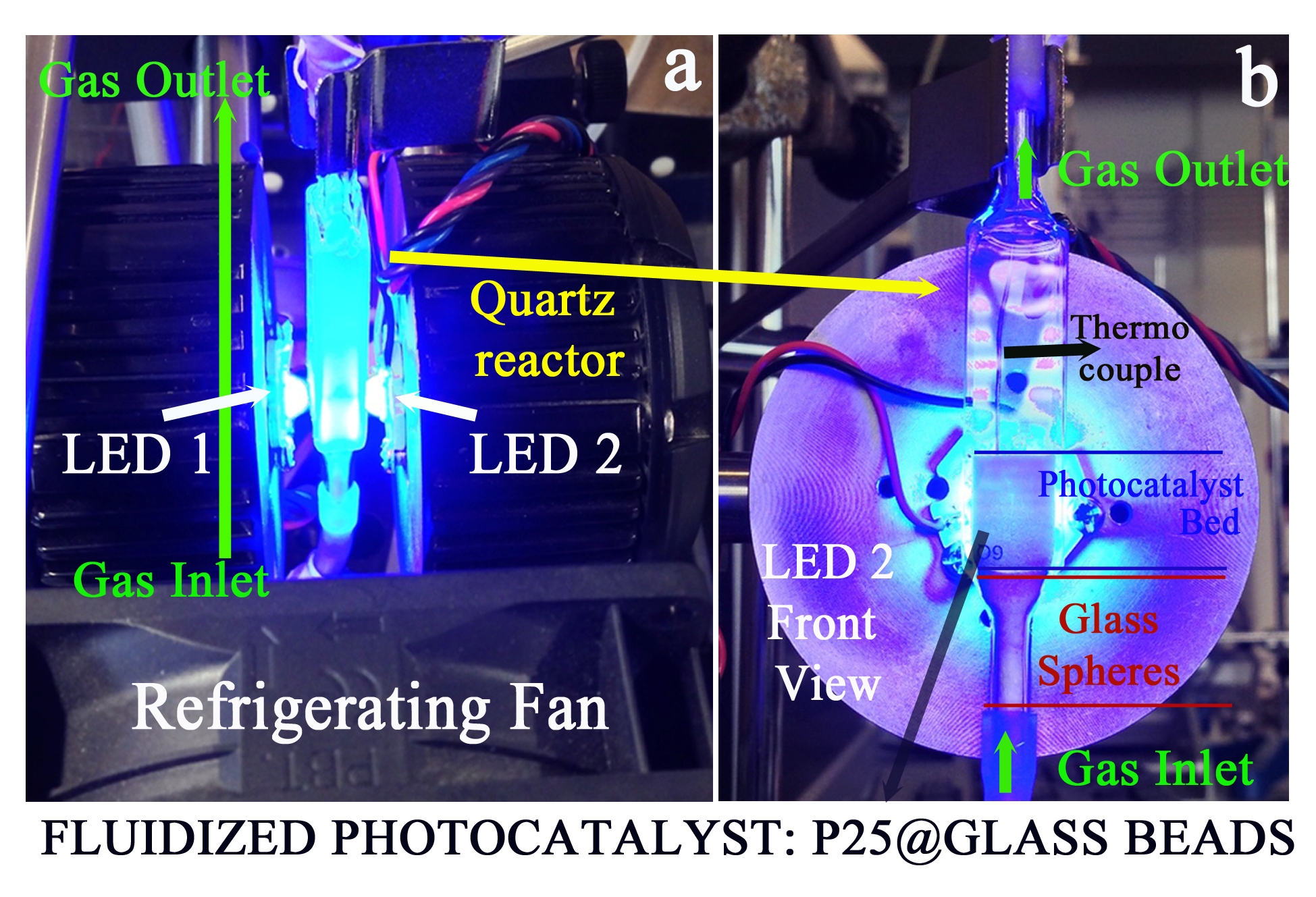

Photocatalytic pathways are expected to open up new possibilities in chemical processing by reducing activation barriers and enhancing reaction kinetics. However, the yields obtained are often limited due to the trade-off between the catalyst mass available and the intensity of light reaching the catalyst. The recent rapid advances in light emitting diode (LED) technology, including high irradiance devices from ultraviolet to infrared light allows unprecedented design flexibility and cost efficiency.

Our approach

We aim to design new photo-assisted reactors that allow higher throughput processing For this topic, we are developing new photo-catalysts based on semiconducting oxides (TiO2, ZnO) and a variety of dopants, e.g. carbon based (carbon dots, g-C3N4), and metallic nanoparticles such as Ni, Cu, Co or Fe (to cite a few). Our aim is to extend the absorption span and also to exploit photothermal effects, in addition to photocatalytic routes. We are also exploring diverse configurations of photoreactors for both batch and continuous operation. Some examples include fixed bed reactors, membrane photoreactors and fluidized bed photoreactors with a large illumination area. While our main emphasis is on gas phase reactions (CO2 reduction and VOC degradation) we are also developing photoreactors for liquid phase environmental applications.

Scheme of a high-irradiance LED bed reactors for CO2 hydrogenation

Highlighted and recent publications

- LED-driven controlled deposition of Ni onto TiO2 for visible-light expanded conversion of carbon dioxide into C1–C2 alkanes. Sanz-Marco, A. et al.; Nanoscale Advances, 3, 3788-3798, (2021) https://doi.org/10.1039/D1NA00021G

- Anisotropic Au-ZnO photocatalyst for the visible-light expanded oxidation of n-hexane. Bueno-Alejo, C. et al.; Catalysis Today, Volume 362, 97-103 (2021) https://doi.org/10.1016/j.cattod.2020.03.063

- LED-driven continuous flow carbon dioxide hydrogenation on a nickel-based catalyst. Bueno-Alejo, C. et al.; Catalysis Today, Volume 355, 678-684 (2020) https://doi.org/10.1016/j.cattod.2019.06.022

- High-radiance LED driven fluidized bed photoreactor for the complete oxidation of n-hexane in air, Bueno-Alejo, C.J. et al. Chem. Eng. J., 358 1363 (2019) https://doi.org/10.1016/j.cej.2018.09.223

- Silver-Copper Oxide Heteronanostructures for the Plasmonic-Enhanced Photocatalytic Oxidation of N-Hexane in the Visible-NIR Range, Suarez, H. et al. Materials (2019) https://doi.org/10.3390/ma12233858

Contact persons

Balas, Francisco: fbalas@unizar.es

Hueso, José Luis: jlhueso@unizar.es

Santamaría, Jesús: Jesus.Santamaria@unizar.es

Sebastián, Víctor: victorse@unizar.es

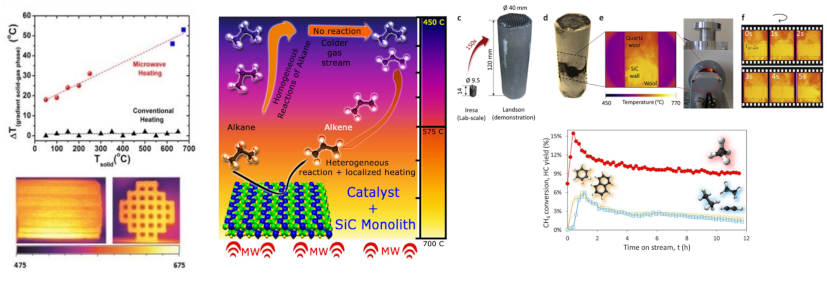

CATALYSTS CAPABLE OF DIRECT HEATING IN A MICROWAVE FIELD

In an ideal catalytic contactor, the energy necessary for the reaction would be exclusively delivered to the active sites of the catalyst. This is not the case with conventional operation of catalytic reactors, where heat is generally supplied through the reactor wall, leading to unnecessary heating of the fluid phase, catalyst support and reactor materials.

In contrast, direct catalyst heating would provide better energy efficiency, as well as other benefits including a higher selectivity in many reacting systems (e.g. series-parallel reacting networks with a valuable intermediate product, where further reaction would be prevented cooler surroundings, or reactions at high temperature where competition from homogeneous pathways is significant).

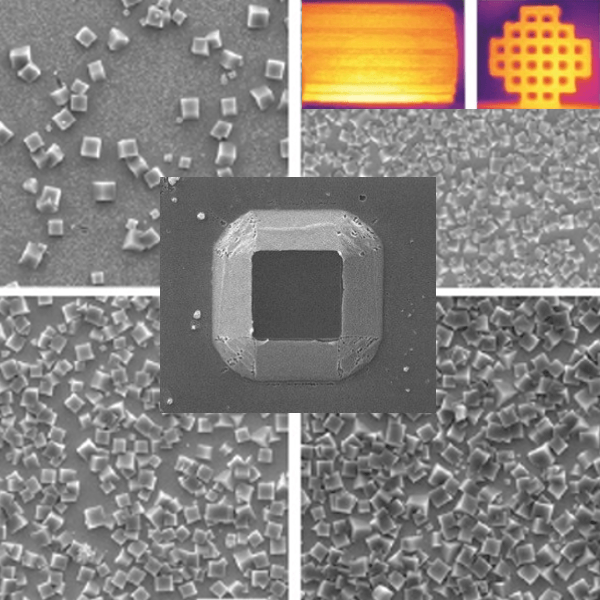

Our approach

We use microwave heating of suitable solids to deliver energy directly and efficiently to the target material that then becomes hotter than the surrounding fluid. This allows operating with a stable solid-gas temperature gap, typically in the 50-150 K range (see figure). However, implementation of this concept is not straightforward, as it involves a re-design of the reactor to allow penetration of the microwave field, and a suitable selection of catalytic materials and/or supports (zeolites, carbon-based catalysts, perovskites, catalysts on SiC supports, etc.), that need to be sensitive to microwaves.

As recent examples of the advantages of this technology, we have employed it in selective oxidations (1-2), VOC removal (3), methane reforming (3-4), suppression of gas phase reactions (5) and non-oxidative methane conversion (4)

Figure: Left: Example of temperature differences between the solid and the gas phase when subjected to microwave heating during Isobutane oxidative dehydrogenation with CO2 including pictures of a MW-sensitive SiC monolith onto which the desired catalyst can be deployed. It can be seen that SiC monolith heats homogeneously under MW irradiation (temperature scale from 475 to 675 oC); (Centre): Schematic display of the homogeneous and heterogeneous reaction pathways occurring under MW irradiation (the former being prevented due to the lower gas phase temperature); (Right): MW enhanced revalorization of methane on scaled-up SiC monoliths.

Some recent highlighted publications

- Gas-solid contactors and catalytic reactors with direct microwave heating: Current status and perspectives. Hueso, J.L., Mallada, R., Santamaria, (in press) Catalysis Today. https://doi.org/10.1016/j.cattod.2022.10.009

- From bench scale to pilot plant: A 150x scaled-up configuration of a microwave-driven structured reactor for methane dehydroaromatization. Julian I., Pedersen C.M, Jensen A.B,

Baden A.K, Hueso J.L, Friderichsen A.V, Birkedal H, Mallada R, Santamaria J. (2022) Catalysis Today, 383, pp. 21-30. https://doi.org/10.1016/j.cattod.2021.04.013 - Intensified microwave-assisted heterogeneous catalytic reactors for sustainable chemical manufacturing. Chen W, Malhotra A, Yu K, Zhenga W, Plaza-Gonzalez P.J, Catala-Civera J.M, Santamaria J, Vlachos D.G. Chem. Eng. J., Volume 420, (2021), 130476 https://doi.org/10.1016/j.cej.2021.130476

- Non-oxidative methane conversion in microwave-assisted structured reactors. Julian, I., Ramirez, H., Hueso, J.L., Mallada, R., Santamaria, J. Chem. Eng. J 377, art. no. 119764, (2019). https://doi.org/10.1016/j.cej.2018.08.150

- Escaping undesired gas phase chemistry: Microwave-driven selectivity enhancement in heterogeneous catalytic reactors, A. Ramirez, J.L. Hueso, M. Abian, U. Alzueta, R. Mallada, J. Santamaria, Science Advances, 5:eaau9000, (2019). https://doi.org/10.1126/sciadv.aau9000

Contact persons

Hueso, José Luis: jlhueso@unizar.es

Mallada, Reyes: rmallada@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

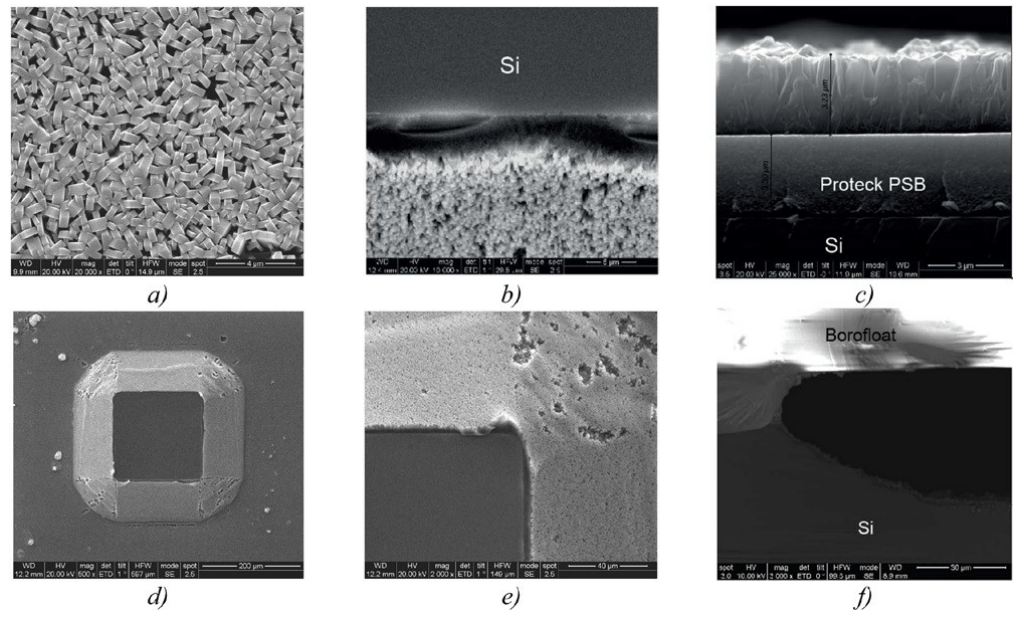

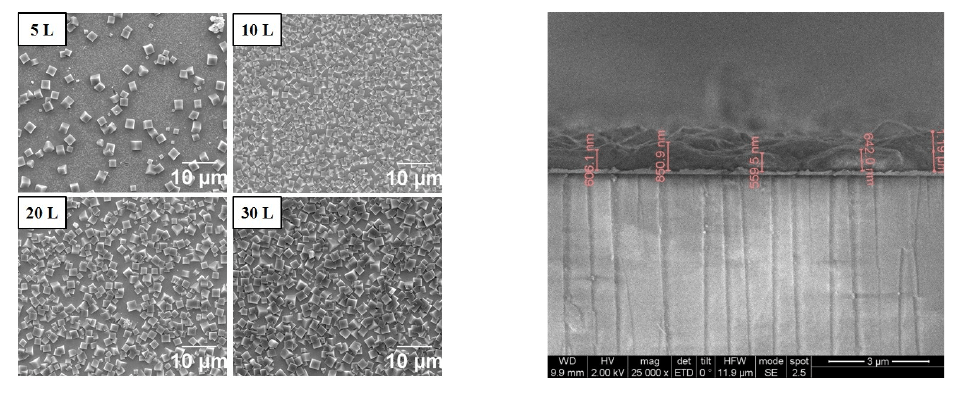

MICROCONCENTRATORS FOR COMPOUNDS AT TRACE CONCENTRATION LEVELS

Lab-on-a-chip microdevices have found great acceptance in many fields such as bioassays, chemical reactions, separation, sensing platforms, to name a few. Miniaturization allows the integration of several processes into a single portable device, and introduces additional advantages such as new functionalities, better interaction between components, reduced power consumption reduction or lower manufacturing cost. Microdevices built as pre-concentrators are also a promising alternative to solve one of the main challenges faced by present day analytical devices: the reliable detection of compounds at trace concentration levels below ppb.

Our approach

Concentrating the target analyte in a stage prior to the detection unit substantially improves detector response in terms of sensitivity and selectivity. We aim to achieve this by: i) selecting selective specific adsorbents and deploying them as low-inertia thin films on microchannels, ii) designing the micro-concentrator in such a way that optimum gas/solid contact is achieved, and iii) designing an integrated, fast response heating scheme to enable sudden desorption of the adsorbed molecule, thus achieving the desired concentration factor. Unlike the majority of MEMS preconcentrators where commercial common sorbents are deployed, we pursue the fabrication of microdevices where the amount, type and configuration of nanoporous sorbent material (e.g. zeolites, MOFs) is optimized for each specific application, with the aim of attaining a large contact area with a low sorbent mass.

Figure: SEM images of silicalite-1 microconcentrators: top view of silicalite-1 film grown on the microchannel (a); top view of intersection between silicalite-1 layer and Si after lift-off process (b); cross-section of silicalite-1 layer grown onto Proteck PSB® resist before lift-off process(c); details of pillared structures (d) and (e); and cross-section of the final sealed microconcentrator device (f).

Figure: SEM images of Si micro-preconcentrators based on the MOF5 analogue Zn4O(dmcapz)3 as a function of the number of Layer by Layer (LbL) cycles: top view (left); cross section for 20 LbL cycles (right).

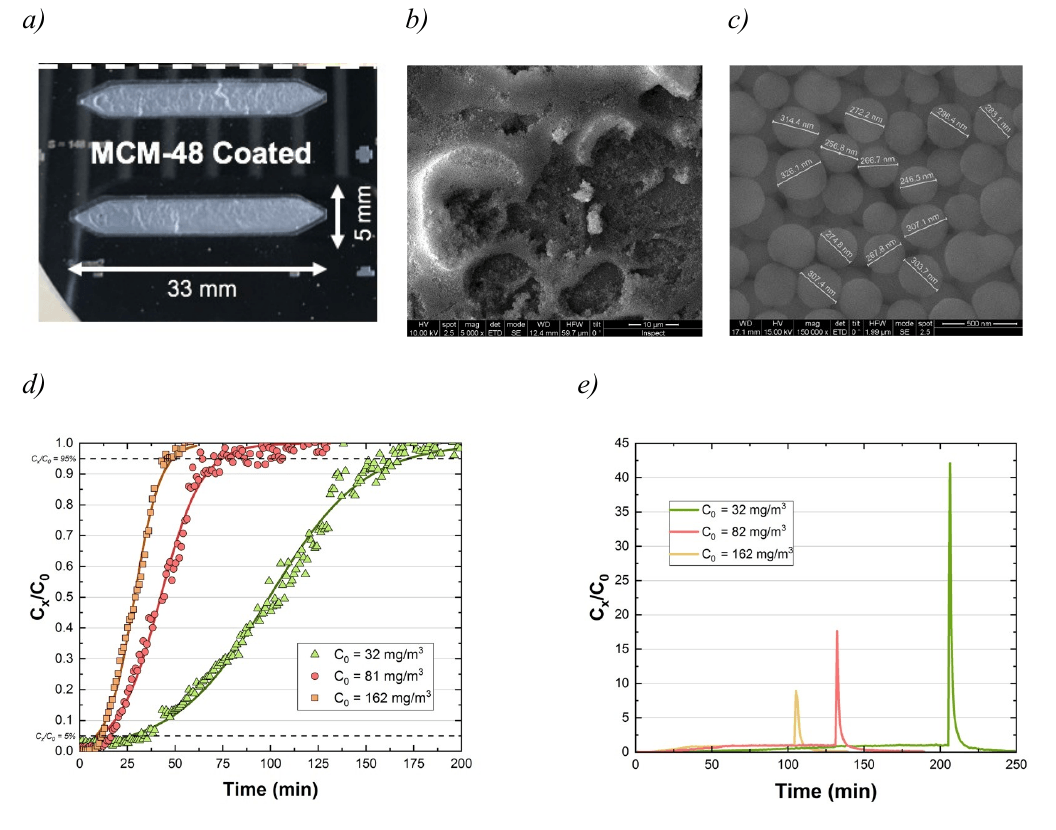

Figure: MCM-48-coated micro-preconcentrators for neurotoxic agents sampling at trace level: optical image of the microfluidic device (43 x 15 x 1 mm, with 33 x 5 x 0.06 mm microchannel (a); SEM images of the MCM-48-coated chip, circa 3 μm in thickness for the MCM-48 coating (b) and (c); dynamic retention capacity of MCM-48-coated micro-preconcentrators (d) and adsorption-desorption experiments for different dimethyl methylphosphonate DMMP (simulant of neurotoxic agents) concentrations (e).

Some recent related publications

- Cu-BTC functional microdevices as smart tools for capture and preconcentration of nerve agents. Almazan, F., Urbiztondo, M., Serra-Crespo, P., Seoane, B., Gascon, J., Santamaria, J., Pina, M.P. ACS Appl. Mater. Interfaces, (2020) https://doi.org/10.1021/acsami.0c07364

- µ-Preconcentrators Using Protic Imidazolium Polyionic Liquids for Chemical Warfare Agents Sampling at Trace Level. Almazán, F., Val, L., Urbiztondo, M., Santamaría, J., Pina, M.P. 20 th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII https://doi.org/10.1109/TRANSDUCERS.2019.8808734

- SERS detection of neurotoxic agents in gas phase using microfluidic chips containing gold-mesoporous silica as plasmonic sorbent. M. Lafuente, M., Almazán, F., Bernad, E., Val, Urbiztondo, M., Santamaría, J., Mallada, R., Pina, M.P. 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII https://doi.org/10.1109/TRANSDUCERS.2019.8808289

- Zeolite based microconcentrators for volatile organic compounds sensing at trace-level: fabrication and performance. Almazán, F., Pellejero,I., Morales, A., Urbiztondo, M., Sesé, J., Pina, M.P., Santamaría, J. Journal of Micromechanics and Microengineering. 26-8, 084010 (2016). https://doi.org/10.1088/0960-1317/26/8/084010

Contact persons

Mallada, Reyes: rmallada@unizar.es

Pina, María Pilar: mapina@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

Urbiztondo, Miguel: urbiz@unizar.es

Nanomedicine

- Nanomaterials As Vectors For Drug Delivery

- Nanomaterials As Vectors For Remote Hyperthermia

- Catalysis Against Cancer

NANOMATERIALS AS VECTORS FOR DRUG DELIVERY

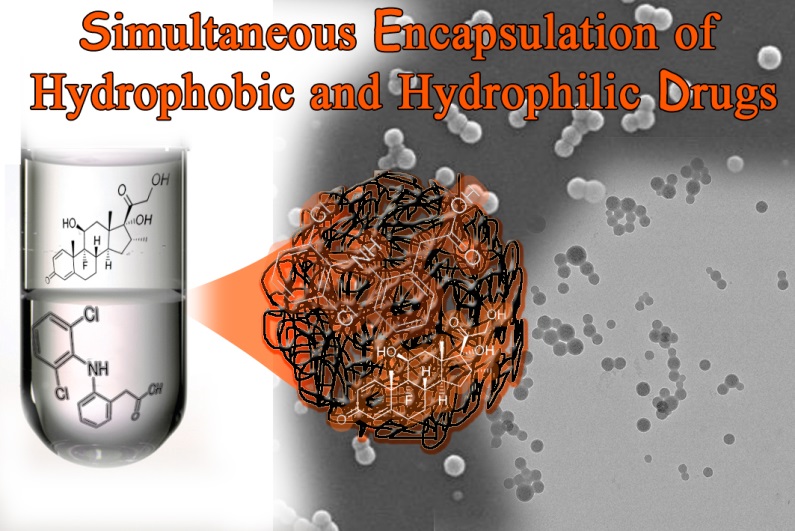

As carriers of drugs, genes or other bioactive molecules nanomaterials have shown improved solubility, amended pharmacokinetics and reduced collateral side effects compared to the administration of the free drug. Ideally, we expect a drug release system to deliver the drug only where and when it is needed. However, this is still highly challenging, and involves overcoming many obstacles: sufficiently high drug load, avoidance of the immune system, on-demand activation and targeted delivery, to name a few.

Our approach

We develop drug delivery carriers using continuous microfluidic synthesis, which also allows large-scale production. We focus mainly on polymeric carriers, (e.g. PLGA, chitosan and thermoresponsive polymers) to obtain a sustained or on demand drug release depending on the needs. We design carriers not only for parenteral administration but also pulmonary (via aerosols), enteral and topical delivery. In addition, we include as key research topic theragnostic nanoparticles to address both therapy and diagnosis within the same vector. Finally, we develop Trojan-Horse strategies based on emerging delivery vehicles, such as stem cells or exosomes as emerging carriers to achieve selective delivery of therapeutic loads to the target cells.

Figure: Schematic representation of a suspension composed of drug loaded PLGA nanoparticles zooming in a single particle.

Some recent related publications

- X-Ray Photoelectron Spectroscopy (XPS) analysis of nitrogen environment in exosomal membranes. A potential novel technique with application for cancer screening”, M. Sancho-Albero, A. Martin-Pardillos, S. Irusta, V. Sebastian, V. L. Cebolla, R. Pazo-Cid, M.P. Martin-Duque, J. Santamaria, Cancers, 15, 2479, (2023)10.3390/cancers15092479

- Exosomes loaded with ultrasmall Pt nanoparticles: A novel low-toxicity alternative to cisplatin”, M Sancho-Albero, A. Martín-Pardillos, L. Luján, V. Sebastian, J. Santamaría, M.P. Martín-Duque, J. Nanobiotechnol., 20, 473, (2022). https://doi.org/10.1186/s12951-022-01675-4

- Engineering alginate-based dry powder microparticles to a size suitable for direct pulmonary delivery of antibiotics”, B. Arauzo, A. Garcinuño, A. Tabernero, J. Calzada, M.P. Lobera, E.M. Del Valle, J. Santamaria, Pharmaceutics, 14, 2763, (2022). https://doi.org/10.3390/pharmaceutics14122763

- High Performance Thin-Layer Chromatography Densitomery-Tandem ESI-MS to evaluate phospholipids content in exosomes of cancer cells”, M. Sancho-Albero, C. Jarne, M. Savirón, P. Martín-Duque, L. Membrado, V. L. Cebolla, J. Santamaría, Int. J. Molec. Sciences, 23, 1150, (2022). https://doi.org/10.3390/ijms23031150

- Transfer of photothermal nanoparticles using stem cell derived extracellular vesicles for in vivo treatment of primary and multinodular tumors”, M. Sancho-Albero, M. Encinas, V. Sebastián, E. Pérez, L. Luján, J. Santamaría, P. Martin-Duque, J. Extracell. Vesicles, 2022;11:e12193 (2022). 10.1002/jev2.12193

- Non-destructive production of exosomes loaded with ultrathin Palladium nanosheets for targeted bioorthogonal catalysis, V. Sebastian, M. Sancho-Albero, M. Arruebo, A.M. Perez-Lopez, B. Rubio-Ruiz, M.P. Martin-Duque, A. Unciti-Broceta, J. Santamaria, Nature Protocols, 16, 131-63, (2021). 10.1038/s41596-020-00406-z

- Excipient-free inhalable microparticles of azithromycin produced by electrospray: a novel approach to direct pulmonary delivery of antibiotics, B. Arauzo, T. B. Lopez-Mendez , M. P. Lobera, J. Calzada, J.L. Pedraz, J. Santamaria, Pharmaceutics, 13, 1988, (2021). https://doi.org/10.3390/pharmaceutics13121988

Contact persons:

Hueso, José Luis: jlhueso@unizar.es

Lobera, Pilar: plobera@unizar.es

Martin-Duque, Pilar; mariadelpilar.martin@unizar.es

Martin Pardillos, Ana: a.martin_pardillos@unizar.es

Sancho-Albero, María: msancho@unizar.es

Santamaria, Jesus: jesus.santamaria@unizar.es

Sebastian, Victor: victorse@unizar.es

NANOMATERIALS AS VECTORS FOR REMOTE HYPERTHERMIA

Hyperthermia-based therapy uses a controlled temperature increase to produce a therapeutic effect, namely, the death of target cells such as bacteria or cancer cells. To be safe and effective, hyperthermia has to be precisely applied, i.e., the effects have to be restricted to a well-defined region, to avoid the unwanted death of healthy cells. In addition, remote activation and deactivation is a desirable feature. Nanoparticles capable to respond to near-infrared (NIR) or magnetic radiation are uniquely suited to perform these tasks.

Our approach

We synthesize nanoparticles with the desired morphology and composition (Au nanoshells and nanorods, Pd nanoslabs, CuS nanoparticles, SPION nanoparticles) to act as radiation targets to enable local hyperthermia. In addition to direct cell killing by a moderate (e.g. 5-10 K) local heating, the temperature increase caused by NIR or magnetic radiation can also be used to trigger the release of a drug. We have used this effect to increase the region of cell death with regards to simple hyperthermia, to spatially pattern gene expression or to release locally therapeutic drugs such as insulin or pain killers (the last application has been studied in the framework of the ERC Consolidator grant NANOHEDONISM). We have also successfully delivered the hyperthermia vectors to the target cells by means of Trojan Horse strategies (with MSCs in vivo and exosomes in vitro).

Figure: Some examples of magnetic (top) and plasmonic (bottom) nanostructures synthesized in our laboratory

Some recent related publications

- Cleavable, thermo-responsive hybrid nanoparticles for on-demand drug delivery. De Solorzano, I.O., et al., J. Colloid. Interf. Sci., 533, 171-81, (2019). https://doi.org/10.1016/j.jcis.2018.08.069

- Exosome origin determines cell targeting and the transfer of therapeutic nanoparticles towards target cells. M. Sancho-Albero et al., J. Nanobiotechnol. 17:16, (2019). https://doi.org/10.1186/s12951-018-0437-z

- Pro-angiogenic semiconductor scaffolds for patterning the expression of therapeutic transgenes. Martin-Saavedra, F.; et al., Acta Biomater., 78, 123-36, (2018). https://doi.org/10.1016/j.actbio.2018.08.006

- Selective Delivery of Photothermal Nanoparticles to Tumors Using Mesenchymal Stem Cells as Trojan-Horses. M. M. Encabo-Berzosa., et al., RSC Adv., 6, 58723-32, (2016). https://doi.org/10.1039/C6RA10058A

- Controlled release of bupivacaine using hybrid thermoresponsive nanoparticles activated via photothermal heating. Alejo, T., et al., J. Colloid. Interf. Sci., 523, 234-44, (2018). https://doi.org/10.1016/j.jcis.2018.03.107

Contact persons

Balas, Francisco: fbalas@unizar.es

Hueso, José Luis: jlhueso@unizar.es

Martin Duque, Pilar: mariadelpilar.martin@unizar.es

Sancho-Albero, María: msancho@unizar.es

Santamaria, Jesus: jesus.santamaria@unizar.es

Sebastian, Victor: victorse@unizar.es

CATALYSIS AGAINST CANCER

Cancer continues to be one of the leading causes of death in spite of decades of intense research efforts. By current estimates, by 2030 over 20 million new cases will be diagnosed yearly, and cancer will cause 13 million deaths worldwide. This is so in spite of a growing toolbox of therapies against cancer that includes Chemotherapy, Radiotherapy, Surgery, Immunotherapy, Precision Medicine and Hormone Therapy, among others. Given the magnitude of this effort, it is noteworthy that Heterogeneous Catalysis, a field recognized for being able to facilitate chemical reactions with high selectivity, has been scarcely explored in oncology. This may be about to change: The emerging fields of bio-orthogonal catalysis and Nanocatalytic medicine in the Tumor Microenvironment are providing new ways to tune the chemistry of complex biological systems, with a myriad of potential applications in diagnosis and therapy.

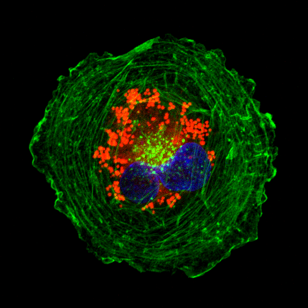

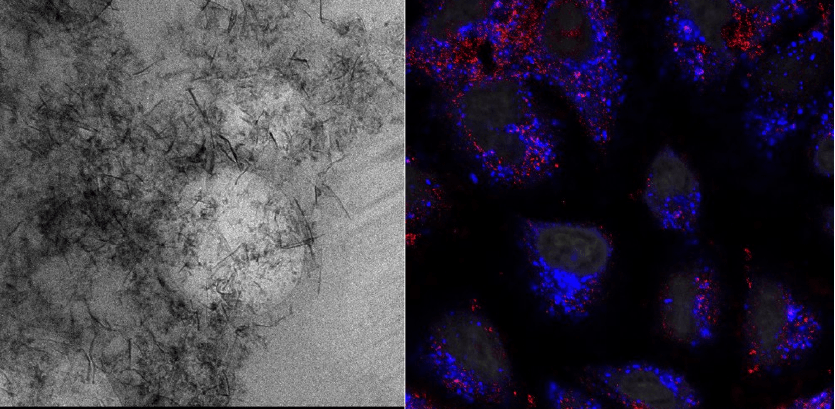

Figure: Left, TEM micrograph showing catalytic Pd-loaded exosomes; Right: Internalization of Pd-loaded exosomes inside cancer cells [4]

Our approach

Within the framework of the ERC Advanced Grant CADENCE we aim to develop catalysts capable of a dual function against cancer: Our catalysts will deplete locally key molecules for cancer growth and/or generate toxic species locally. However, using catalysis as an effective tool against cancer presents enormous challenges: First, catalysts must be able to perform effectively against cancer, under the conditions prevailing in the tumor environment. Also, the catalyst has to be protected from the environment (e.g. from poisoning from sulphur-containing biomolecules). Second, the catalyst must be delivered selectively (or at least preferentially) to the tumor. This is also a formidable challenge, since current methods that rely on the EPR effect or even targeted delivery, present a very low delivery efficiency [Wilhelm et al Nat Rev Mater. 2016)]. For this reason, a variety of alternative delivery methods (e.g. Trojan Horse strategies) are being investigated. Third, ideally the catalyst should be activated only at the tumor site, to avoid side effects in healthy cells. For this, a variety of possibilities exist such as NIRbased activation.

Some recent related publications

- In Cellulo Bioorthogonal Catalysis by Encapsulated AuPd Nanoalloys” B. Rubio-Ruiz, A. M. Pérez-López, L. Usón,M. C. Ortega-Liebana, T. Valero, M. Arruebo, J. L. Hueso, V. Sebastian,. J. Santamaria,.A. Unciti-Broceta, Nano Lett. 23, 804-11, (2023). https://doi.org/10.1021/acs.nanolett.2c03593

- Synergistic assembly of gold and copper-iron oxide nanocatalysts to promote the simultaneous depletion of glucose and glutathione”, J. Bonet-Aleta, J. L. Hueso, L. Sanchez-Uriel, S. Irusta, G. Martinez, J. Santamaria, Mater. Today Chem., 29, 101404, (2023). https://doi.org/10.1016/j.mtchem.2023.101404

- Unveiling the interplay between homogeneous and heterogeneous catalytic mechanisms in copper-iron nanoparticles working under chemically relevant tumour conditions, J. Bonet-Aleta, M. Encinas-Gimenez, E. Urriolabeitia, P. Martin-Duque, J.L. Hueso, J. Santamaria, Chemical Science, 08 Jun (2022).https://doi.org/10.1039/D2SC01379G

- Platinum nanoplatforms: classic catalysts claiming a prominent role in cancer therapy. Garcia-Peiro J.I, Bonet-Aleta J, Santamaria J, Hueso J.L. Chemical Society Reviews, 51, 7662-7681 (2022). DOI: https://doi.org/10.1039/D2CS00518B

- Nondestructive production of exosomes loaded with ultrathin palladium nanosheets for targeted bio-orthogonal catalysis. Sebastian V, Sancho‐Albero M, Arruebo M, Pérez‐López A.M, Rubio‐Ruiz B, Martin‐Duque P, Unciti‐Broceta A, Santamaría J. Nat Protoc (2020) https://doi.org/10.1038/s41596-020-00406-z

- Cancer-derived exosomes loaded with ultrathin Palladium nanosheets for targeted bioorthogonal catalysis. M. Sancho-Albero, B. Rubio-Ruiz, A.M. Perez-Lopez, V. Sebastian, P. Martin-Duque, M. Arruebo, J. Santamaria, A. Unciti-Broceta, Nature Catal., 2, 864–872 (2019). https://doi.org/10.1038/s41929-019-0333-4

Contact persons

Hueso, José Luis: jlhueso@unizar.es

Martin Duque, Pilar: mariadelpilar.martin@unizar.es

Martin Pardillos, Ana: a.martin_pardillos@unizar.es

Sancho-Albero, María: msancho@unizar.es

Santamaría, Jesús: jesus.santamaria@unizar.es

Sebastián, Víctor: victorse@unizar.es